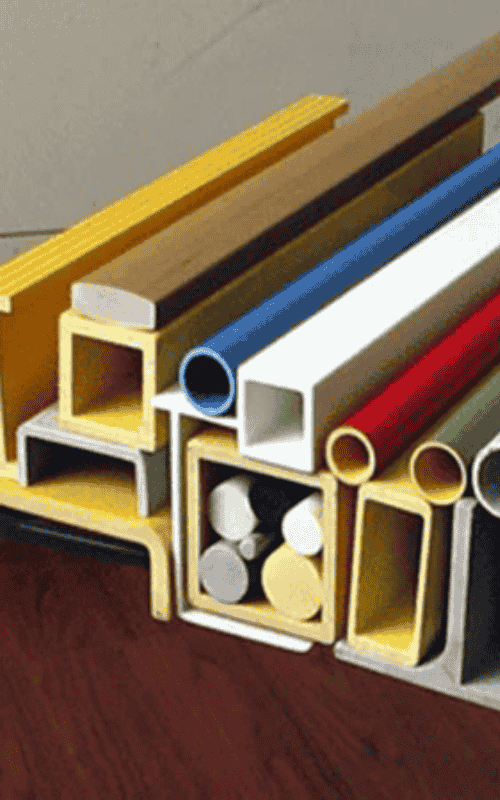

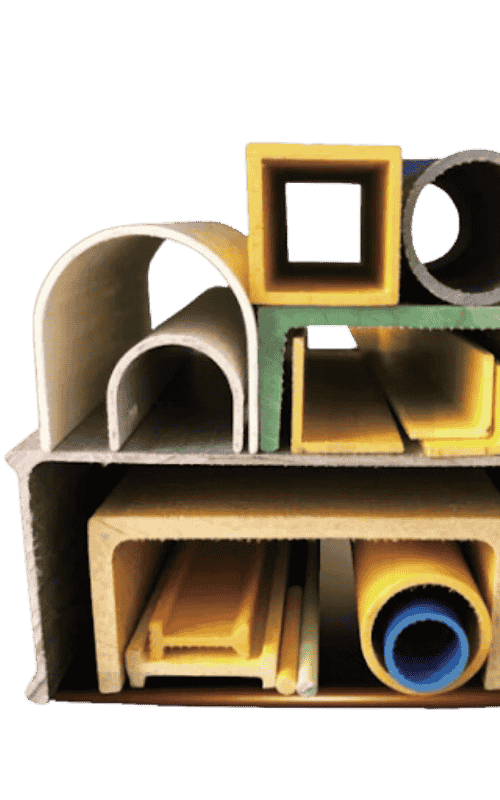

Hand Layup Products

Hand Layup Products are crafted using a manual layering process that allows for the production of complex, custom composite shapes.

This technique offers flexibility in design and material properties, making it suitable for a wide range of applications.

Key Features

Customizable: Tailored Solutions

Allows for the creation of bespoke shapes and sizes to meet specific project needs.

High Strength-to-Weight Ratio: Efficient Performance

Offers high strength while remaining lightweight for ease of use.

Corrosion Resistant: Durable in Harsh Conditions

Ideal for environments exposed to chemicals, moisture, and salt.

Versatile: Wide Application Range

Suitable for various industries, including automotive, aerospace, and construction.

Cost-Effective Production: Affordable Customization

Lower setup and tooling costs compared to automated processes.

Applications

Custom Automotive Parts

Used for specialised components and parts in the automotive industry.

Architectural Elements

Effective for creating custom decorative and structural elements in architecture.

Repair and Replacement

Suitable for manufacturing replacement parts and performing repairs in various industrial applications.

Wind Energy

Ideal for custom components for turbine blades and nacelles, and for manufacturing repair parts.

Railways

Suitable for custom parts and repair solutions for railway infrastructure and rolling stock.